Cut benefits out

Customer needs research allowed us to specify the barriers faced by oxygen and plasma cutting machines during the production of parts from various industries. On the basis of these results our engineers have made every effort to ensure that Dual Flex meets all expectations and becomes an universal tool in production and service plants around the world.

1 - 100 mm cutting and bevelling range

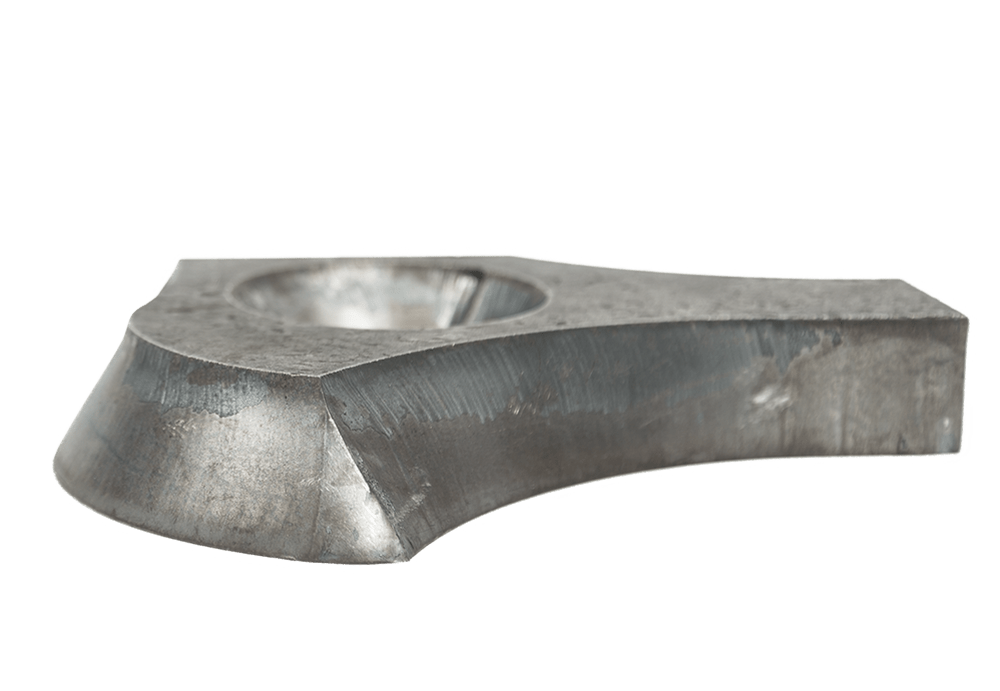

Wide possibilities of chamfering range reduce manufacturing costs significantly

Best bevelling repeat accuracy of the entire thickness range

Stable output quality improves the valuable work time to optimum

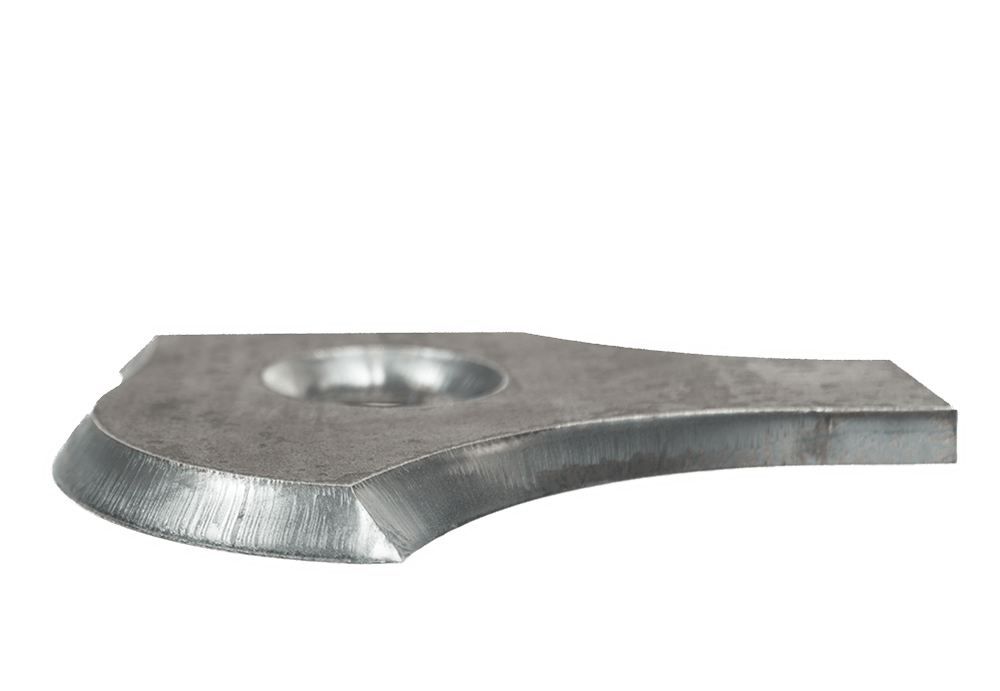

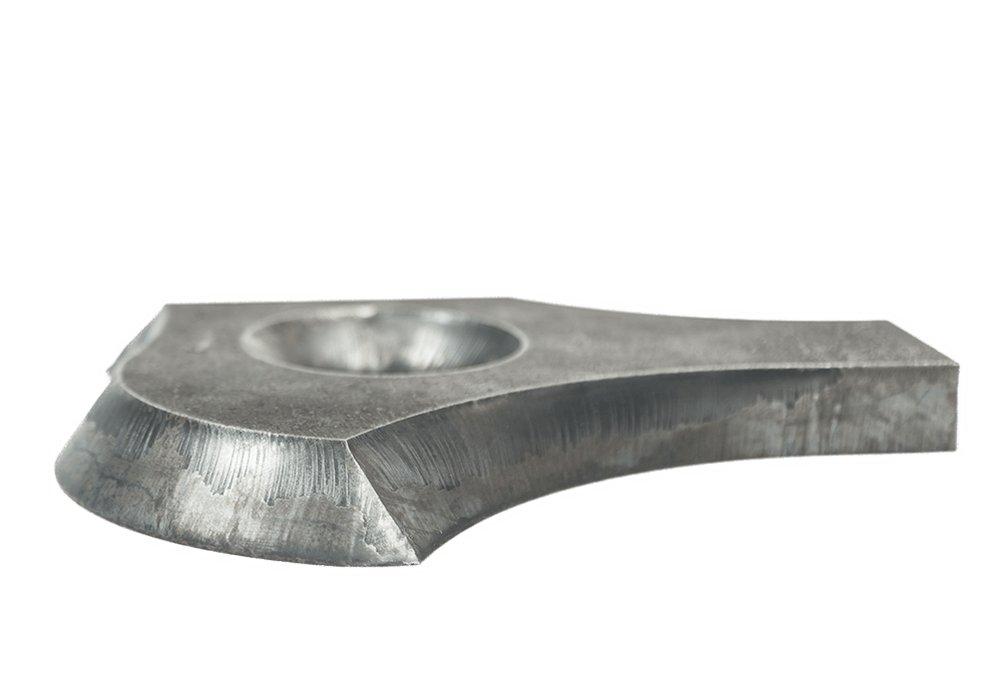

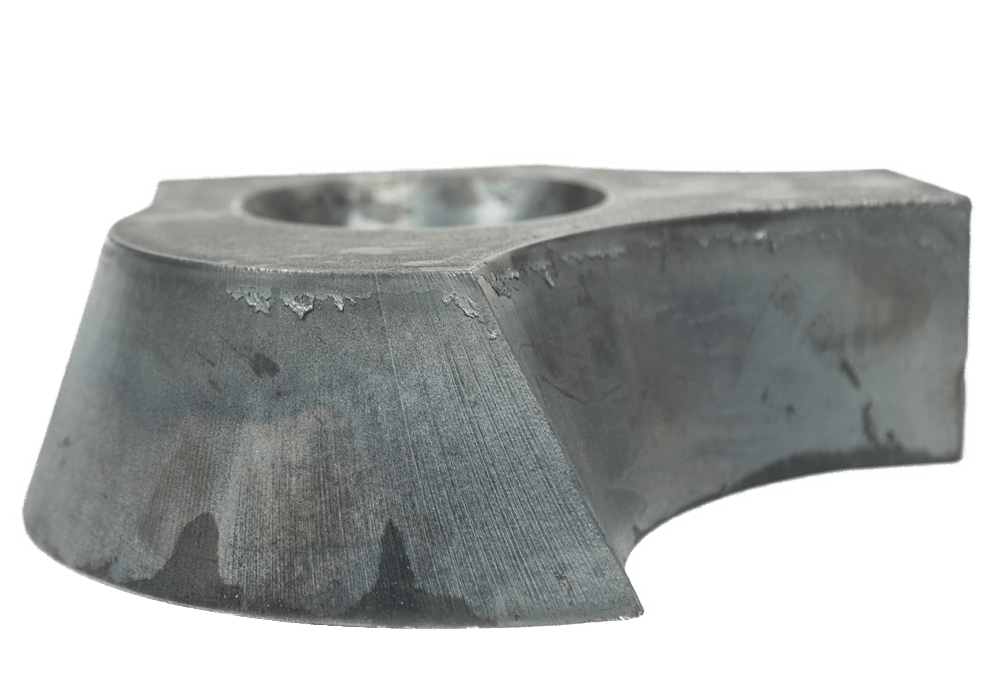

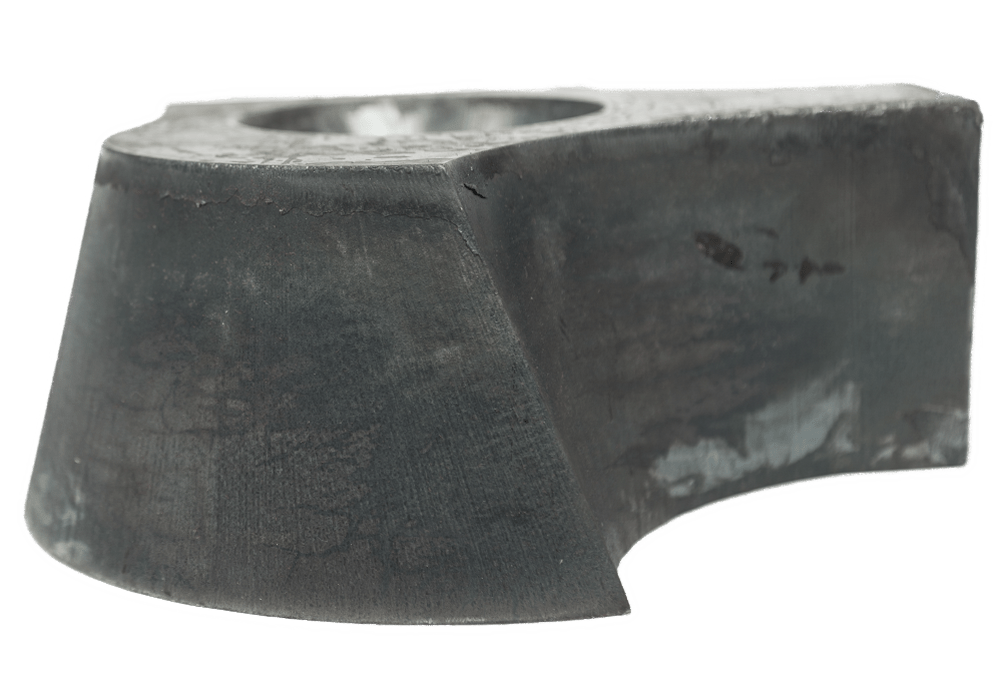

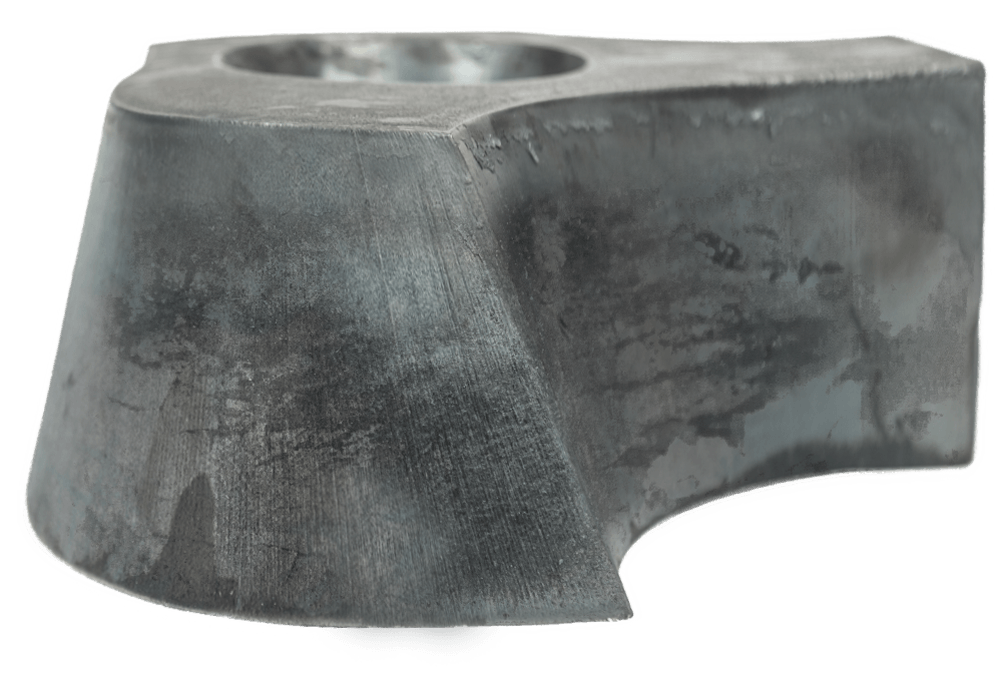

Unique quality of cut edges

Optimum cut accuracy ensures perfect post processing conditions for workers

New face of production efficiency

Material utilization, energy consumption, noise level and pollution at welding preparation are reduced to a minimum compared to manual work

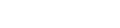

12 mm

20 mm

30 mm

60 mm

80 mm

100 mm

Discover the power

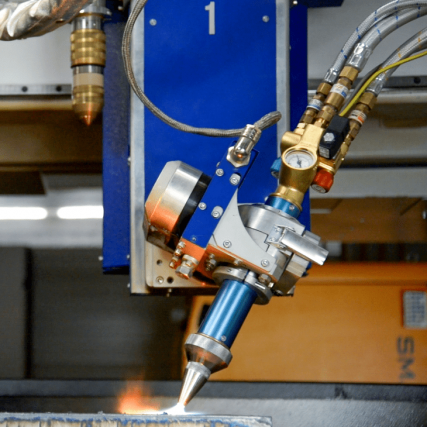

A completely new dimension of plasma-oxygen cutting.

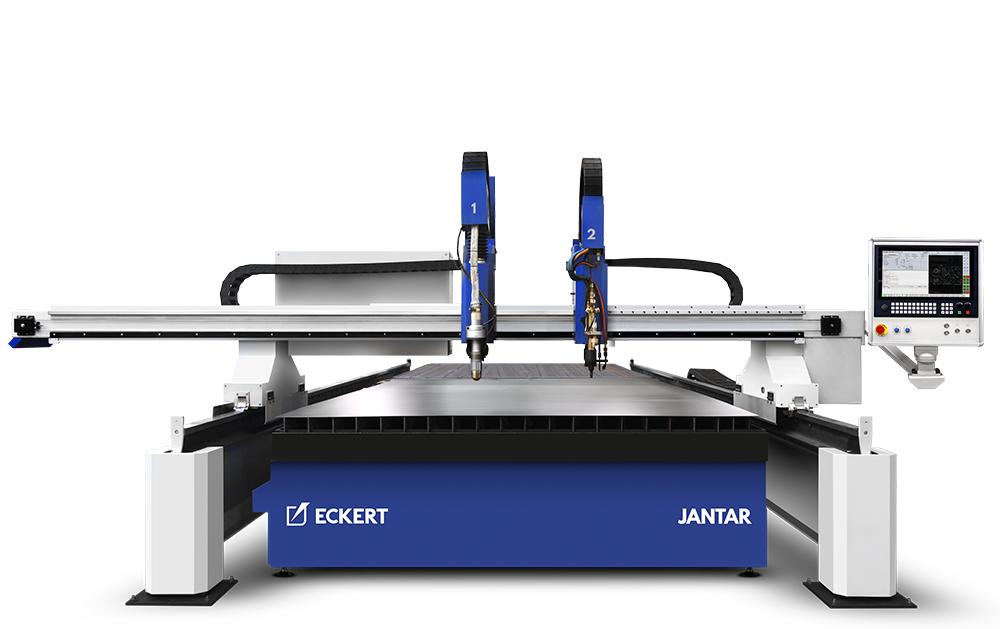

Two exchangeable torches guarantee the best possible cutting quality in the shift system

Dual Flex 3D

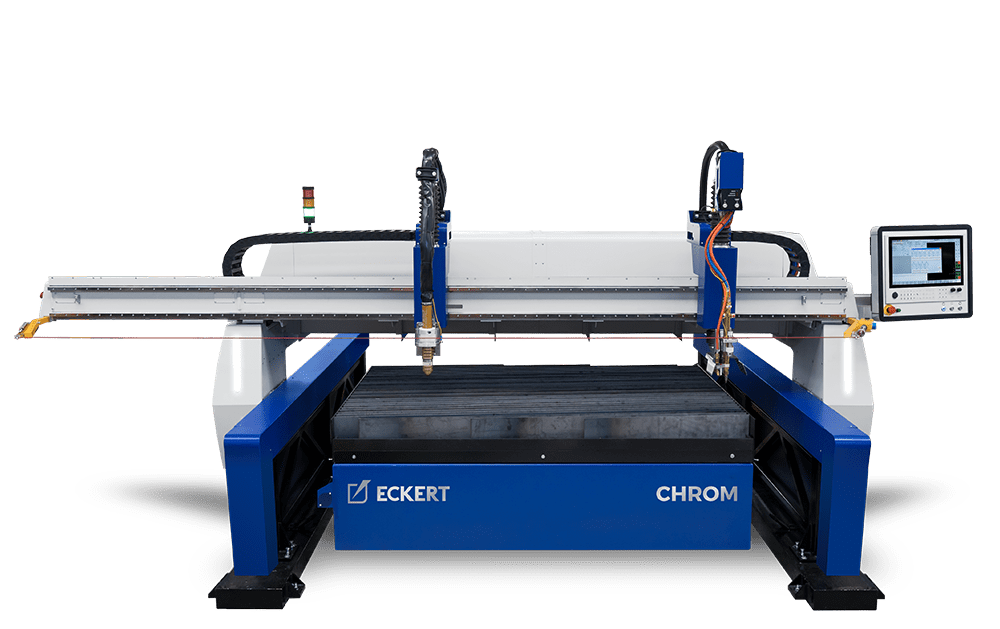

It is wrong to believe that everything has already been done to improve the oxy cutting technology. The newest solutions in the field of full autonomy of oxygen cutting include, among others, optimization of all stages of the process (heating, piercing, cutting).

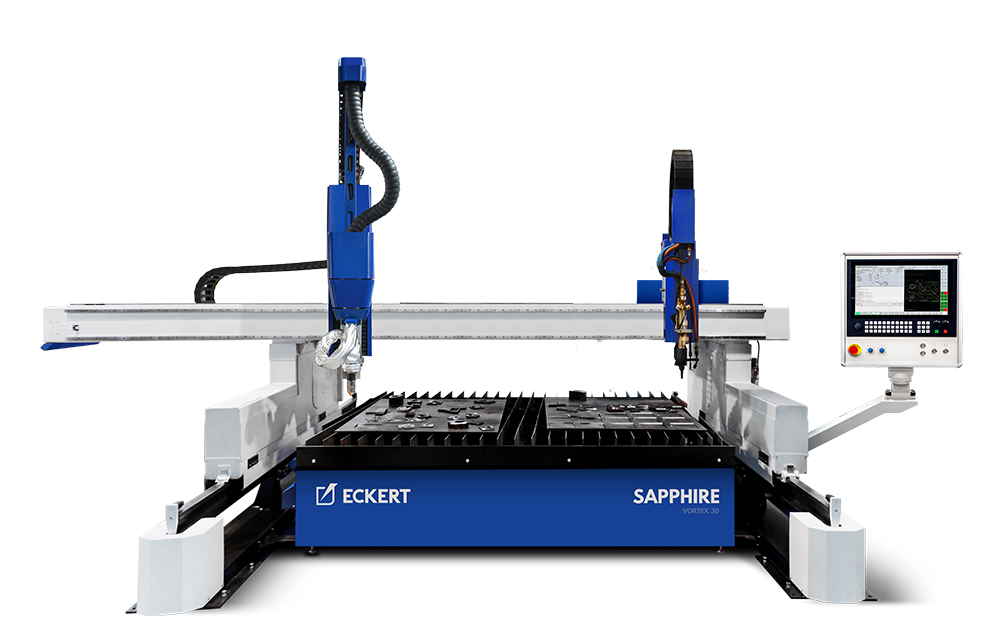

3D plasma cutting

Head angle deflection +/- 52° provides a powerful bevelling tool in three dimensions.

3D oxygen cutting

The possibility of machining at an angle of +/- 45° and the revolutionary oxygen cutting system provides extra wide ranges of welding preparation.

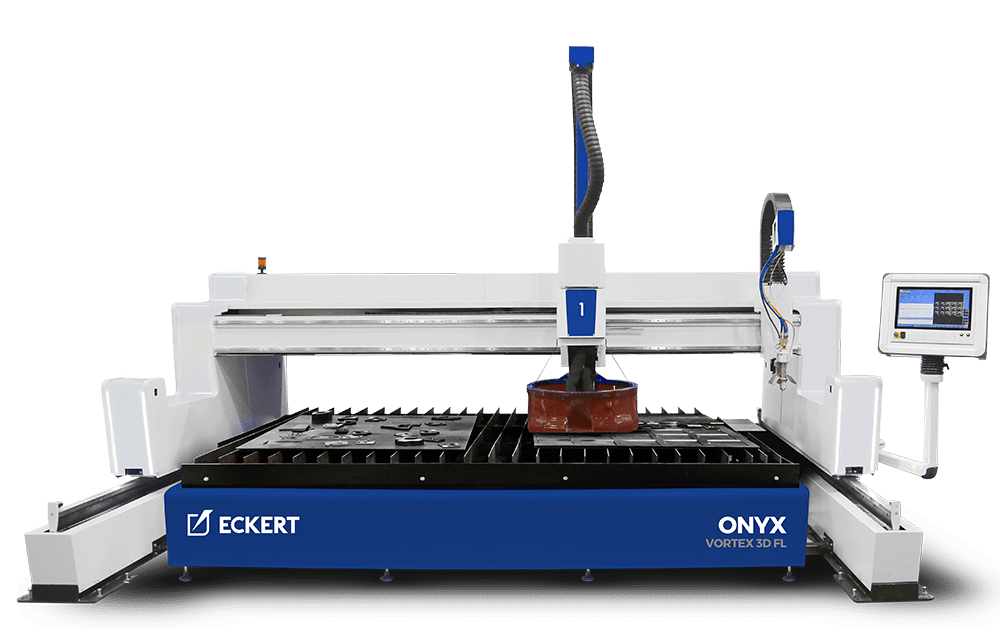

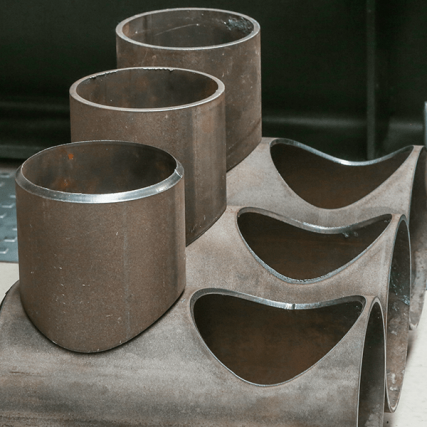

Tube and profile cutting

Cutting with 3D technology in combination with a rotator gives the possibility of creating complex tubular structures together with the preparation of welding bevels.

Autonomous Oxycut

Revolutionary full process automation ensured by sensor packages and software development boosts the efficiency of oxygen cutting.

Dual Flex parameters

Customer needs research allowed us to specify the barriers faced by oxygen and plasma cutting machines during the production of parts from various industries. On the basis of these results our engineers have made every effort to ensure that Dual Flex meets all expectations and becomes an universal tool in production and service plants around the world.

3D CUTTING PARAMETERS

A & C axis maximal deflection

52°

Oxygen cutting bevels

VAS, VDS, I

Plasma cutting bevels

VAS, VDS, YAS, YDS, I, K, X

Oxygen torch sensors

Mechanical Touch, Anti-collision, Capacitive

Plasma torch sensors

Intelligent Distance Control (IDC), Mechanical Touch, Electrical Touch, Anti-collision

2in1

Two technologies for 3D/2D cutting (plasma & oxygen)

NASA™ technology

Innovative strain wave gearing resistant to extreme conditions

Simply clever

Quick tool change thanks to self-positioning holders

For taskmasters

Cutting and bevelling plates, tubes, and profiles in wide thickness range

Safety first

Sensor packages protect the workers and ensure stable cut process flow

Precision

Linear bearings in the Z axis ensure high rigidity and smooth operation

Why Eckert?

Because we are customer-focused. Each project is carefully crafted according to individual needs and expectations.

Experienced team

Our experts from industry share knowledge with our customers, caring for every little need during very close long term cooperation

Source of solutions

Eckert offers not only machines but complex after-sale services. Our global network ensures quick parts availability.

Super service

Remotely or at your place - our service technicians work hard within the whole country.

Trust

For over 30 years, we have installed over 1,800 cutting machines in 36 countries around the world. Check what we can do for you.

We are happy to help - contact us!

Do you want to see the possibilities with your own eyes?

You can make an appointment in our company, watch a remote show online, but also send us a file or specify your needs, and we will provide a cutting sample to you, so that you can see for yourself the highest quality of cutting

Contact

Eckert AS Sp. z o.o.

ul. Pawicka 4c

59-220 Legnica

dolnośląskie, Polska

E-mail: eckert@eckert.com.pl

tel: +48 (76) 852 20 17

Copyright © 2022 Eckert Sp. z o. o.

Powered by Marketing – Eckert Sp. z o. o.